|

Qingdao Xindacheng Plastic Machinery CO., LTD.

|

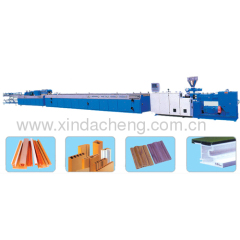

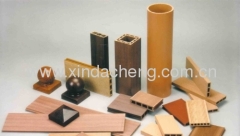

Wood-Plastic Profile Extrusion Lines

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This production line is widely used in produce floor, siding board, decking board, garden furniture, tray, etc.

I. Designed according to characteristics of wood and plastic, professional manufacturing, and stable function

Ii. Able to save 40% energy compared to two step machines

Iii. Less area covered and less investment on fixed assets

Iv. Less workers needed to operate the machines

V. Less times of plastic processing, to reduce loss of plastic and avoid degrading its performance

Vi. Able to expel moisture and gas easily because of several vents designed

Vii. Long time of using time (7200hrs at least).

Ii. Able to save 40% energy compared to two step machines

Iii. Less area covered and less investment on fixed assets

Iv. Less workers needed to operate the machines

V. Less times of plastic processing, to reduce loss of plastic and avoid degrading its performance

Vi. Able to expel moisture and gas easily because of several vents designed

Vii. Long time of using time (7200hrs at least).

| Machine Type | Length-diameter Ratio | Rotational Speed (r/min) | Total Power (KW) | Output (Kg/h) | Outline Dimension (mm) | Total Weight (Kg) |

| SWMSY-1 | 10-32 | 30-80 | 75 | 40-60 | 13500*1050*2400 | 4900 |

| SWMSY-2 | 10-32 | 30-60 | 103 | 70-120 | 21860*2000*3200 | 7800 |

| SWMSY-3 | 10-32 | 30-60 | 126 | 90-180 | 22580*2200*3200 | 8900 |

Related Search

Plastic Profile Extrusion Line

Plastic Extrusion Profile

Wood Plastic Profile

Wood Plastic Extrusion Line

Wood Plastic Extrusion

Wood Plastic Extrusion Machinery

More>>