|

Qingdao Xindacheng Plastic Machinery CO., LTD.

|

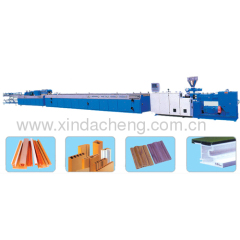

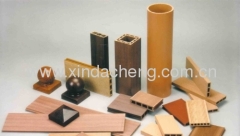

WPC profile

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This production line is widely used in produce floor, siding board, decking board, garden furniture, tray, etc.

Features:

1) This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber, and the material is of 90% of waste plastic and waste natural fiber

2) With scientific and reasonable technology, the machine has high efficiency and runs stably

3) With both properties of wood and plastic, the WPC products are of high stiffness and impact performance. The ratio of performance and price is muchhigher than wood and plastic

4) The WPC products can be recycled 100%, so they are environment-friendly products

Equipment advantages:

1) The parallel twin screw extruder is used to mix the wood and plastic, and get good homogeneous melt

2) It uses single screw extruder as the second stage to build the pressure to extrude the final product

3) It adopts both advantages of single screw extruder and parallel twin screw extruder

4) Wood fiber can be 70% in the WPC products due to the good mixing effect, so the cost of WPC product is low

5) Four-step vacuum exhaust to get good exhausting and dehumidifying effect

6) If the natural moisture is less than 10%, the dryer is not needed

7) It saves investment and energy

8) The material and screw are made from special alloy, so the service life is longer than other equipment

9) This is one step WPC extrusion technology, which saves energy

10) The parallel twin screw extruder is of building block structure, so it can produce variety of plastic through adjusting the screw

1) This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber, and the material is of 90% of waste plastic and waste natural fiber

2) With scientific and reasonable technology, the machine has high efficiency and runs stably

3) With both properties of wood and plastic, the WPC products are of high stiffness and impact performance. The ratio of performance and price is muchhigher than wood and plastic

4) The WPC products can be recycled 100%, so they are environment-friendly products

Equipment advantages:

1) The parallel twin screw extruder is used to mix the wood and plastic, and get good homogeneous melt

2) It uses single screw extruder as the second stage to build the pressure to extrude the final product

3) It adopts both advantages of single screw extruder and parallel twin screw extruder

4) Wood fiber can be 70% in the WPC products due to the good mixing effect, so the cost of WPC product is low

5) Four-step vacuum exhaust to get good exhausting and dehumidifying effect

6) If the natural moisture is less than 10%, the dryer is not needed

7) It saves investment and energy

8) The material and screw are made from special alloy, so the service life is longer than other equipment

9) This is one step WPC extrusion technology, which saves energy

10) The parallel twin screw extruder is of building block structure, so it can produce variety of plastic through adjusting the screw

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!